Clog making

Zeeland was once big when it came to clog making. Nowadays, it is an endangered artisanal craft. But there are still a few clog makers active who make these wooden shoes. Many people nowadays buy them as souvenirs, but there are still quite a few Zeelanders who walk on clogs every day for practical reasons.

East Zeeuws-Vlaanderen and Zuid-Beveland

For a lot of farmworkers, making wooden shoes provided a welcome source of extra income. Clog making was concentrated in East Zeeuws-Vlaanderen (particularly around Clinge) and also on Zuid-Beveland. Even though clogs are considered typically Dutch, many clog makers in the border region actually hailed from Flanders. There were quite a few people involved in this. At the beginning of the 20th century, Zeeland had 675 clog makers. Almost two-thirds came from East Zeeuws-Vlaanderen. While Brabant was the quintessential clog region, Zeeland still accounted for 10 percent, and in 1950, even 20 percent, of all Dutch clogs.

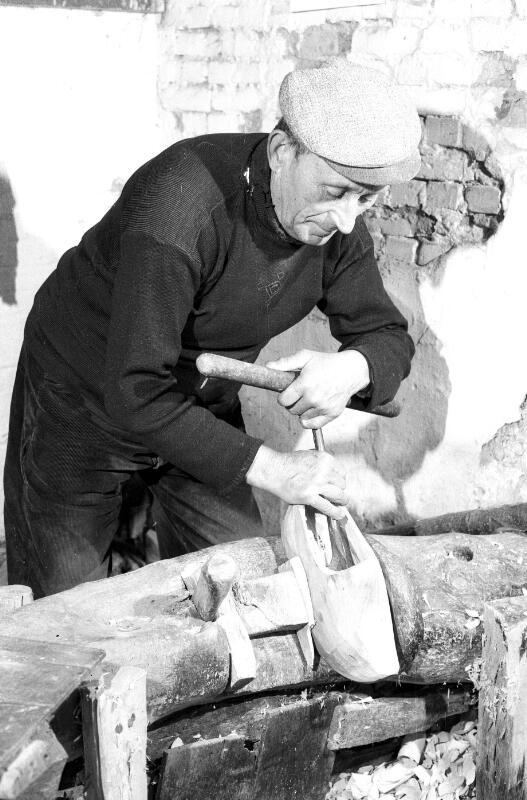

Clog maker B. de Couwer in Clinge with a spoon auger, 1965 (ZB, Beeldbank Zeeland, photo C. Kotvis).

Use

Clogs were the favourite footwear of the poor. As ‘work shoes’, they were comfortable, practical and safe. The greatest advantage: a foot in a clog does not get stuck so easily. Even today, many Zeelanders still wear clogs to work. And they are not just farmers, but street pavers too, for example.

The traditional handcraft

Making clogs is not easy. Clog makers learned their trade on the job and it took them years to master it. The clog maker sawed tree trunks (usually poplar or willow) into wedge-shaped pieces. From all those pieces, he then made a clog-like shape with a ’dissel’ (a special kind of axe). The clog was fastened to a bracket and shaped further. Then the clog was fastened nose-down on a workbench and drilled out even further. The clog maker then carved out and smoothed out the inside and outside using a bottom knife. After that, it was just a matter of drying them out for a few weeks. The clogs were then ready. A good clog maker could make about six to eight pairs of clogs in one long working day.

Mechanisation

In the 20th century, mechanisation was essential in order to be able to produce on a larger scale and more cheaply. Clog maker Traas in Heinkenszand was one of the first to make the transition. He installed motors to drive his machinery as early as the 1930s. It all happened very quickly. Of the 350 clog makers in Zeeuws-Vlaanderen, only 50 were still working manually in 1950.

Clog maker De Couwer drilling out a clog, 1965 (ZB, Image Bank Zeeland, photo C. Kotvis).

Making clogs by machine

Basically, the mechanical manufacturing process does not differ that much from the manual one. Tree trunks are also sawn into wedge-shaped blocks here. It is important that the wood is a little wet, otherwise cracks may form. The clog makers have moulds and the pieces of wood are put into a copying machine to create the same shape as the moulds. Then the clogs are hollowed out using a drilling machine. Everything is accurate down to the last millimetre. If a different size has to be made, the clog makers can easily spend a whole day readjusting the machinery. So this is not an easy craft either. But it is a much more fast-paced craft. The copying machine produces about forty pairs of clogs per hour.

Clogs in the fine drilling machine owned by clog maker Traas, 2020 (Erfgoed Zeeland, photo Vera Dorst).

The finish

The roughly-hewn clogs have to dry for a few days. Then they are sanded down thoroughly. This can also be done by machine. Only the back and front are sanded by hand. Some of the clogs remain natural in colour, but many are also painted. The traditional yellow clogs with black and red details are the most popular. Those patterns, by the way, differ per clog maker. Therefore, you can tell by looking at a pair of clogs which clog maker they came from. Besides the traditional colours, wooden shoes are nowadays painted in all kinds of other cheerful colours.

Exciting future

Not many clog makers are left, due to bankruptcies and a lack of successors. There are only two left in Zeeland. Near Groede, you will come across Boyd Rotteveel who is the only one in Zeeland who still makes clogs by hand. You can visit his workshop if you want to see or buy a pair of clogs. He also gives demonstrations for groups. At his workshop, he keeps a collection of 28 clogs from all over the world and he also has a beautiful pair of self-made bridal clogs decorated with wood carvings.

The Traas company in Heinkenszand is the only mechanised clog factory in Zeeland. This clog maker offers guided tours and you can pick out clogs in all kinds of shapes and sizes in the shop.